Industrial

Revolution

Computerized Textile Mill

This photo demonstrates how much

textile production has changed as a result of industrialization. In this modern

textile mill, many machines whir busily in an initial stage of processing fiber

into fabric. The process is almost entirely coordinated and controlled by

computer, with a small staff of managers, inspectors, and technicians to ensure

quality and efficiency.

Industrial Revolution, widespread replacement

of manual labor by machines that began in Britain in the 18th century and is

still continuing in some parts of the world. The Industrial Revolution was the

result of many fundamental, interrelated changes that transformed agricultural

economies into industrial ones. The most immediate changes were in the nature

of production: what was produced, as well as where and how. Goods that had

traditionally been made in the home or in small workshops began to be

manufactured in the factory. Productivity and technical efficiency grew

dramatically, in part through the systematic application of scientific and

practical knowledge to the manufacturing process. Efficiency was also enhanced

when large groups of business enterprises were located within a limited area.

The Industrial Revolution led to the growth of cities as people moved from

rural areas into urban communities in search of work.

The changes brought by

the Industrial Revolution overturned not only traditional economies, but also

whole societies. Economic changes caused far-reaching social changes, including

the movement of people to cities, the availability of a greater variety of

material goods, and new ways of doing business. The Industrial Revolution was

the first step in modern economic growth and development. Economic development

was combined with superior military technology to make the nations of Europe

and their cultural offshoots, such as the United States, the most powerful in

the world in the 18th and 19th centuries.

The Industrial Revolution

began in Great Britain during the last half of the 18th century and spread

through regions of Europe and to the United States during the following

century. In the 20th century industrialization on a wide scale extended to

parts of Asia and the Pacific Rim. Today mechanized production and modern

economic growth continue to spread to new areas of the world, and much of

humankind has yet to experience the changes typical of the Industrial

Revolution.

The Industrial Revolution

is called a revolution because it changed society both significantly and

rapidly. Over the course of human history, there has been only one other group

of changes as significant as the Industrial Revolution. This is what

anthropologists call the Neolithic Revolution, which took place in the later

part of the Stone Age. In the Neolithic Revolution, people moved from social

systems based on hunting and gathering to much more complex communities that

depended on agriculture and the domestication of animals. This led to the rise

of permanent settlements and, eventually, urban civilizations. The Industrial

Revolution brought a shift from the agricultural societies created during the

Neolithic Revolution to modern industrial societies.

Richard Trevithick

British engineer Richard

Trevithick pioneered the use of steam power for locomotion in the 1790s and

1800s. In 1804 he constructed the first practical steam locomotive operating on

a railway and demonstrated its use for hauling large loads.

The social changes brought

about by the Industrial Revolution were significant. As economic activities in

many communities moved from agriculture to manufacturing, production shifted

from its traditional locations in the home and the small workshop to factories.

Large portions of the population relocated from the countryside to the towns

and cities where manufacturing centers were found. The overall amount of goods

and services produced expanded dramatically, and the proportion of capital

invested per worker grew. New groups of investors, businesspeople, and managers

took financial risks and reaped great rewards.

In the long run the Industrial

Revolution has brought economic improvement for most people in industrialized

societies. Many enjoy greater prosperity and improved health, especially those

in the middle and the upper classes of society. There have been costs, however.

In some cases, the lower classes of society have suffered economically.

Industrialization has brought factory pollutants and greater land use, which

have harmed the natural environment. In particular, the application of

machinery and science to agriculture has led to greater land use and,

therefore, extensive loss of habitat for animals and plants. In addition,

drastic population growth following industrialization has contributed to the

decline of natural habitats and resources. These factors, in turn, have caused

many species to become extinct or endangered.

|

II

|

GREAT BRITAIN LEADS THE WAY

|

Adam Smith

In his famous treatise, The

Wealth of Nations, Adam Smith argued that private competition free from

regulation produces and distributes wealth better than government-regulated

markets. Since 1776, when Smith produced his work, his argument has been used

to justify capitalism and discourage government intervention in trade and

exchange. Smith believed that private businesses seeking their own interests

organize the economy most efficiently, “as if by an invisible hand.”

Ever since the Renaissance

(14th century to 17th century), Europeans had been inventing and using ever

more complex machinery. Particularly important were improvements in

transportation, such as faster ships, and communication, especially printing.

These improvements played a key role in the development of the Industrial

Revolution by encouraging the movement of new ideas and mechanisms, as well as

the people who knew how to build and run them.

Then, in the 18th century

in Britain, new production methods were introduced in several key industries,

dramatically altering how these industries functioned. These new methods

included different machines, fresh sources of power and energy, and novel forms

of organizing business and labor. For the first time technical and scientific

knowledge was applied to business practices on a large scale. Humankind had

begun to develop mass production. The result was an increase in material goods,

usually selling for lower prices than before.

The Industrial Revolution

began in Great Britain because social, political, and legal conditions there

were particularly favorable to change. Property rights, such as those for

patents on mechanical improvements, were well established. More importantly,

the predictable, stable rule of law in Britain meant that monarchs and

aristocrats were less likely to arbitrarily seize earnings or impose taxes than

they were in many other countries. As a result, earnings were safer, and

ambitious businesspeople could gain wealth, social prestige, and power more

easily than could people on the European continent. These factors encouraged

risk taking and investment in new business ventures, both crucial to economic

growth.

In addition, Great Britain’s

government pursued a relatively hands-off economic policy. This free-market

approach was made popular through Scottish philosopher and economist Adam Smith

and his book The Wealth of Nations (1776). The hands-off policy permitted fresh

methods and ideas to flourish with little interference or regulation.

Britain’s nurturing social

and political setting encouraged the changes that began in a few trades to

spread to others. Gradually the new ways of production transformed more and

more parts of the British economy, although older methods continued in many

industries. Several industries played key roles in Britain’s industrialization.

Iron and steel manufacture, the production of steam engines, and textiles were

all powerful influences, as was the rise of a machine-building sector able to

spread mechanization to other parts of the economy.

|

A

|

Changes in Industry

|

Modern industry requires

power to run its machinery. During the development of the Industrial Revolution

in Britain, coal was the main source of power. Even before the 18th century,

some British industries had begun using the country’s plentiful coal supply

instead of wood, which was much scarcer. Coal was adopted by the brewing,

metalworking, and glass and ceramics industries, demonstrating its potential

for use in many industrial processes.

|

A1

|

Iron and Coal

|

A major breakthrough in

the use of coal occurred in 1709 at Coalbrookedale in the valley of the Severn

River. There English industrialist Abraham Darby successfully used coke—a

high-carbon, converted form of coal—to produce iron from iron ore. Using coke

eliminated the need for charcoal, a more expensive, less efficient fuel. Metal

makers thereafter discovered ways of using coal and coke to speed the

production of raw iron, bar iron, and other metals.

The most important advance

in iron production occurred in 1784 when Englishman Henry Cort invented new

techniques for rolling raw iron, a finishing process that shapes iron into the

desired size and form. These advances in metalworking were an important part of

industrialization. They enabled iron, which was relatively inexpensive and

abundant, to be used in many new ways, such as building heavy machinery. Iron

was well suited for heavy machinery because of its strength and durability.

Because of these new developments iron came to be used in machinery for many

industries.

Iron was also vital to

the development of railroads, which improved transportation. Better

transportation made commerce easier, and along with the growth of commerce

enabled economic growth to spread to additional regions. In this way, the

changes of the Industrial Revolution reinforced each other, working together to

transform the British economy.

|

A2

|

Steam

|

Matthew Boulton

English manufacturer and engineer

Matthew Boulton financed and introduced James Watt’s steam engine, which became

the most important source of power during the Industrial Revolution. The two

men became partners in the steam-engine business in 1775 and obtained a 25-year

extension of the patent. Boulton and Watt shared many technological innovations

with other companies, increasing the spread of industrialization.

If iron was the key metal

of the Industrial Revolution, the steam engine was perhaps the most important

machine technology. Inventions and improvements in the use of steam for power

began prior to the 18th century, as they had with iron. As early as 1689,

English engineer Thomas Savery created a steam engine to pump water from mines.

Thomas Newcomen, another English engineer, developed an improved version by

1712. Scottish inventor and mechanical engineer James Watt made the most

significant improvements, allowing the steam engine to be used in many

industrial settings, not just in mining. Early mills had run successfully with

water power, but the advancement of using the steam engine meant that a factory

could be located anywhere, not just close to water.

Parts of a Steam Engine

Harnessing the power of steam

marked a significant step in technology. The introduction of the steam engine

led to many new inventions, most notably in transportation and industry. Steam

engines transfer the energy of heat into mechanical energy, often by allowing

steam to expand in a cylinder equipped with a movable piston. As the piston

moves up and down (or alternatively, from side to side), an attached arm

converts this motion into parallel motion that drives a wheel. Models of the steam

engine were designed as early as 1690, but it was not until 70 years later that

James Watt arrived at the design of the modern steam engine.

In 1775 Watt formed an

engine-building and engineering partnership with manufacturer Matthew Boulton.

This partnership became one of the most important businesses of the Industrial

Revolution. Boulton & Watt served as a kind of creative technical center

for much of the British economy. They solved technical problems and spread the

solutions to other companies. Similar firms did the same thing in other

industries and were especially important in the machine tool industry. This

type of interaction between companies was important because it reduced the

amount of research time and expense that each business had to spend working

with its own resources. The technological advances of the Industrial Revolution

happened more quickly because firms often shared information, which they then

could use to create new techniques or products.

James Watt (1736-1819)

Scottish inventor James Watt

(1736-1819) made vast improvements to the steam engine, making it practical for

large-scale industrial use. In 1764 Watt was given a Newcomen steam engine to

repair. While working on the engine, he realized that it wasted energy. He

eventually introduced a variety of modifications, including a separate cooling

chamber for the steam that made the engine much more efficient.

Like iron production,

steam engines found many uses in a variety of other industries, including

steamboats and railroads. Steam engines are another example of how some changes

brought by industrialization led to even more changes in other areas.

|

A3

|

Textiles

|

Sir Richard Arkwright

In 1769 British inventor Richard

Arkwright patented his spinning frame, which spun cotton fiber into thread.

Arkwright established huge cotton mills that became the models for the factory

system of the Industrial Revolution.

The industry most often

associated with the Industrial Revolution is the textile industry. In earlier

times, the spinning of yarn and the weaving of cloth occurred primarily in the

home, with most of the work done by people working alone or with family

members. This pattern lasted for many centuries. In 18th-century Great Britain

a series of extraordinary innovations reduced and then replaced the human labor

required to make cloth. Each advance created problems elsewhere in the

production process that led to further improvements. Together they made a new

system to supply clothing.

The first important invention

in textile production came in 1733. British inventor John Kay created a device

known as the flying shuttle, which partially mechanized the process of weaving.

By 1770 British inventor and industrialist James Hargreaves had invented the

spinning jenny, a machine that spins a number of threads at once, and British

inventor and cotton manufacturer Richard Arkwright had organized the first

production using water-powered spinning. These developments permitted a single

spinner to make numerous strands of yarn at the same time. By about 1779

British inventor Samuel Crompton introduced a machine called the mule, which

further improved mechanized spinning by decreasing the danger that threads

would break and by creating a finer thread.

Flyer Spinning Frame

Introduced by Richard Arkwright

in 1769, the flyer spinning frame (also called the throstle or roll-drawing

machine) reflects the move toward automation that characterized the Industrial

Revolution. The machine is powered by the drive wheel at the bottom, drawing

out the fiber into thread, then twisting it as it is wound onto the bobbins.

Throughout the textile

industry, specialized machines powered either by water or steam appeared. Row

upon row of these innovative, highly productive machines filled large, new

mills and factories. Soon Britain was supplying cloth to countries throughout

the world. This industry seemed to many people to be the embodiment of an

emerging, mechanized civilization.

The most important results

of these changes were enormous increases in the output of goods per worker. A

single spinner or weaver, for example, could now turn out many times the volume

of yarn or cloth that earlier workers had produced. This marvel of rising

productivity was the central economic achievement that made the Industrial

Revolution such a milestone in human history.

|

B

|

Changes in Society

|

The Industrial Revolution

also had considerable impact upon the nature of work. It significantly changed

the daily lives of ordinary men, women, and children in the regions where it

took root and grew.

|

B1

|

Growth of Cities

|

Newcastle upon Tyne, England

Many towns throughout Britain

became manufacturing centers during the Industrial Revolution in the 18th and

19th centuries. Newcastle upon Tyne, in northeastern England, became important

for steel production and shipbuilding.

One of the most obvious

changes to people’s lives was that more people moved into the urban areas where

factories were located. Many of the agricultural laborers who left villages

were forced to move. Beginning in the early 18th century, more people in rural

areas were competing for fewer jobs. The rural population had risen sharply as

new sources of food became available, and death rates declined due to fewer

plagues and wars. At the same time, many small farms disappeared. This was

partly because new enclosure laws required farmers to put fences or hedges

around their fields to prevent common grazing on the land. Some small farmers

who could not afford to enclose their fields had to sell out to larger

landholders and search for work elsewhere. These factors combined to provide a

ready work force for the new industries.

Textile Mill in Lancashire,

England

The textile industry was one of

the first industries to be mechanized in 18th-century Britain. These women

worked in a textile mill in Lancashire, in northwestern England.

New manufacturing towns

and cities grew dramatically. Many of these cities were close to the coalfields

that supplied fuel to the factories. Factories had to be close to sources of

power because power could not be distributed very far. The names of British

factory cities soon symbolized industrialization to the wider world: Liverpool,

Birmingham, Leeds, Glasgow, Sheffield, and especially Manchester. In the early

1770s Manchester numbered only 25,000 inhabitants. By 1850, after it had become

a center of cotton manufacturing, its population had grown to more than

350,000.

In preindustrial England,

more than three-quarters of the population lived in small villages. By the

mid-19th century, however, the country had made history by becoming the first

nation with half its population in cities. By 1850 millions of British people

lived in crowded, grim industrial cities. Reformers began to speak of the mills

and factories as dark, evil places.

|

B2

|

Effects on Labor

|

Division of Labor in Industry

Division of labor is a basic

tenet of industrialization. In division of labor, each worker is assigned to a

different task, or step, in the manufacturing process, and as a result, total

production increases. As this illustration shows, one person performing all

five steps in the manufacture of a product can make one unit in a day. Five

workers, each specializing in one of the five steps, can make 10 units in the

same amount of time.

The movement of people

away from agriculture and into industrial cities brought great stresses to many

people in the labor force. Women in households who had earned income from

spinning found the new factories taking away their source of income.

Traditional handloom weavers could no longer compete with the mechanized

production of cloth. Skilled laborers sometimes lost their jobs as new machines

replaced them.

In the factories, people

had to work long hours under harsh conditions, often with few rewards. Factory

owners and managers paid the minimum amount necessary for a work force, often

recruiting women and children to tend the machines because they could be hired

for very low wages. Soon critics attacked this exploitation, particularly the

use of child labor.

The nature of work changed

as a result of division of labor, an idea important to the Industrial

Revolution that called for dividing the production process into basic,

individual tasks. Each worker would then perform one task, rather than a single

worker doing the entire job. Such division of labor greatly improved

productivity, but many of the simplified factory jobs were repetitive and

boring. Workers also had to labor for many hours, often more than 12 hours a

day, sometimes more than 14, and people worked six days a week. Factory workers

faced strict rules and close supervision by managers and overseers. The clock

ruled life in the mills.

By about the 1820s, income

levels for most workers began to improve, and people adjusted to the different

circumstances and conditions. By that time, Britain had changed forever. The

economy was expanding at a rate that was more than twice the pace at which it

had grown before the Industrial Revolution. Although vast differences existed

between the rich and the poor, most of the population enjoyed some of the

fruits of economic growth. The widespread poverty and constant threat of mass

starvation that had haunted the preindustrial age lessened in industrial

Britain. Although the overall health and material conditions of the populace

clearly improved, critics continued to point to urban crowding and the harsh

working conditions for many in the mills.

|

III

|

THE INDUSTRIAL REVOLUTION IN

THE UNITED STATES

|

Interior of the Crystal Palace

Sir Joseph Paxton, an English

landscape gardener and greenhouse architect, designed the Crystal Palace to

house the Great Exhibition of 1851 in London. The Crystal Palace, constructed

entirely of cast iron and glass, expanded notions of architectural beauty. As the

largest structure to be built from prefabricated units up to that time, it also

was a landmark of architectural design, anticipating later industrial

construction.

The economic successes

of the British soon led other nations to try to follow the same path. In

northern Europe, mechanics and investors in France, Belgium, Holland, and some

of the German states set out to imitate Britain’s successful example. In the

young United States, Secretary of the Treasury Alexander Hamilton called for an

Industrial Revolution in his Report on Manufactures (1791). Many Americans felt

that the United States had to become economically strong in order to maintain

its recently won independence from Great Britain. In cities up and down the

Atlantic Coast, leading citizens organized associations devoted to the

encouragement of manufactures.

Alexander Hamilton

Alexander Hamilton was one of the

boldest American political thinkers of his time. As the United States’ first

secretary of the treasury, Hamilton was very influential in setting his country

on the road to industrialization.

The Industrial Revolution

unfolded in the United States even more vigorously than it had in Great

Britain. The young nation began as a weak, loose association of former colonies

with a traditional economy. More than three-quarters of the labor force worked

in agriculture in 1790. Americans soon enjoyed striking success in

mechanization, however. This was clear in 1851 when producers from many nations

gathered to display their industrial triumphs at the first World’s Fair, at the

Crystal Palace in London. There, it was the work of Americans that attracted

the most attention. Shortly after that, the British government dispatched a

special committee to the United States to study the manufacturing accomplishments

of its former colonies. By the end of the century, the United States was the

world leader in manufacturing, unfolding what became known as the Second

Industrial Revolution. The American economy had emerged as the largest and most

productive on the globe.

|

A

|

American Advantages

|

Early Industrial Plant

As the Industrial Revolution

spread to the United States, plants such as this textile factory appeared. Soon

the production of exports outpaced import of goods, and by the late 1800s

America emerged as the world’s largest industrial power.

The United States enjoyed

many advantages that made it fertile ground for an Industrial Revolution. A

rich, sparsely inhabited continent lay open to exploitation and development. It

proved relatively easy for the United States government to buy or seize vast

lands across North America from Native Americans, from European nations, and

from Mexico. In addition, the American population was highly literate, and most

felt that economic growth was desirable. With settlement stretched across the

continent from the Atlantic Ocean to the Pacific Ocean, the United States

enjoyed a huge internal market. Within its distant borders there was remarkably

free movement of goods, people, capital, and ideas.

The young nation also

inherited many advantages from Great Britain. The stable legal and political

systems that had encouraged enterprise and rewarded initiative in Great Britain

also did so, with minor variations, in the United States. No nation was more

open to social mobility, at least for white male Protestants.

Others—particularly African Americans, Native Americans, other minorities, and

women—found the atmosphere much more difficult. In the context of the times,

however, the United States was relatively open to change. It quickly adopted

many of the technologies, forms of organization, and attitudes shaping the new

industrial world, and then proceeded to generate its own advances.

One initial American advantage

was the fact that the United States shared the language and much of the culture

of Great Britain, the pioneering industrial nation. This helped Americans

transfer technology to the United States. As descriptions of new machines and

processes appeared in print, Americans read about them eagerly and tried their

own versions of the inventions sweeping Britain.

Critical to furthering

industrialization in the United States were machines and knowledgeable people.

Although the British tried to prevent skilled mechanics from leaving Britain

and advanced machines from being exported, those efforts mostly proved

ineffective. Americans worked actively to encourage such transfers, even

offering bounties (special monetary rewards) to encourage people with knowledge

of the latest methods and devices to move to the United States.

The most dramatic early

example of a successful technical transfer is the case of Samuel Slater. Slater

was an important figure in a leading British textile firm who sailed to the

United States masquerading as a farmer. He eventually moved to Rhode Island,

where he worked with mechanics, machine builders, and merchants to create the

first important textile mill in the United States. Slater had worked as an

apprentice under Richard Arkwright, and Slater’s mill used Arkwright’s

innovative system of mechanized spinning. The firm of Almy, Brown, and Slater

inspired many imitators and gave birth to a vast textile industry in New

England.

The lure of the open,

growing United States was strong. Its opportunities attracted knowledgeable,

ambitious individuals not only from Britain but from other European countries

as well. In 1800, for example, a young Frenchman named Eleuthère Irénée du Pont

de Nemours brought to the United States his knowledge of the latest French

advances in chemistry and gunpowder making. In 1802 he founded what would

become one of the largest and most successful American businesses, E. I. du

Pont de Nemours and Company, better known simply as DuPont.

|

B

|

American Challenges

|

Telegraph

In 1837 the first electrical telegraph

instruments were invented by Samuel Morse in the United States and by Sir

Charles Wheatstone and Sir William F. Cooke in Britain. Morse sent the first

public telegraph message in 1844. Pictured here is the original Morse receiving

device.

Soon the United States

was pioneering on its own. Because local circumstances and conditions in the

United States were somewhat different than those in Britain, industrialization

also developed somewhat differently. Although the United States had many

natural resources in abundance, some were more plentiful than others. The

profusion of wood in North America, for example, led Americans to use that

material much more than Europeans did. They burned wood widely as fuel and also

made use of it in machinery and in construction. Taking advantage of the vast

forest resources in their country, Americans built the world’s best woodworking

machines.

Transcontinental Railroad

Locomotives from the eastern and

western United States are depicted here meeting in Promontory, Utah, where

crowds gathered to watch the joining of the Union Pacific and Central Pacific

railroads on May 10, 1869. This first transcontinental railroad opened the West

to supplies and resources from the East and served as the chief means of

transportation for settlers in the West.

Transportation and communication

were special challenges in a nation that stretched across the North American

continent. Economic growth depended on tying together the resources, markets,

and people of this large area. Despite the general conviction that private

enterprise was best, the government played an active role in uniting the

country, particularly by building roads. From 1815 to 1860 state and local

governments also provided almost three-quarters of the financing for canal

construction and related improvements to waterways.

Samuel Morse

Samuel F. B. Morse devoted most

of his life to art and politics, and he turned to projects like the telegraph

only as alternative means of supporting his other careers. However, Morse’s

telegraph became the most important 19th-century improvement in communication.

When the British began

building railroads, Americans embraced this new technology eagerly, and

substantial public money was invested in rail systems. By 1860 more than half

the railroad tracks in the world were in the United States. The most critical

19th-century improvement in communication, the telegraph, was invented by

American Samuel F. B. Morse. The telegraph allowed messages to be sent long

distances almost instantly by using a code of electronic pulses passing over a

wire. The railroad and the telegraph spread across North America and helped

create a national market, which in turn encouraged additional improvements in

transportation and communication.

Another challenge in the

United States was a relative shortage of labor. Much more than in continental

Europe or in Britain, labor was in chronically short supply in the United

States. This led industrialists to develop machinery to replace human labor.

|

C

|

Changes in Industry

|

Americans soon demonstrated

a great talent for mechanization. Famed American arms maker Samuel Colt

summarized his fellow citizens’ faith in technology when he declared in 1851,

“There is nothing that cannot be produced by machinery.”

|

C1

|

Continuous-Process

Manufacturing

|

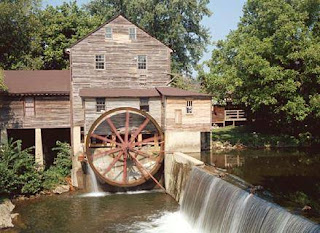

Water-Powered Mill

Early manufacturing employed

water-powered machinery. Water turned the paddles of a wheel, which in turn

moved grinding stones or other mechanical devices. Modern water wheels, called

water turbines, drive generators that produce electricity.

An important American

development was continuous-process manufacturing. In continuous-process

manufacturing, large quantities of the same product, such as cigarettes or

canned food, are made in a nonstop operation. The process runs continuously,

except for repairs to or maintenance of the machinery used. In the late 18th

century, inventor Oliver Evans of Delaware created a remarkable water-powered

flour mill. In Evans’s mill, machinery elevated the grain to the top of the

mill and then moved it mechanically through various processing steps,

eventually producing flour at the bottom of the mill. The process greatly

reduced the need for manual labor and cut milling costs dramatically. Mills

modeled after Evans’s were built along the Delaware and Brandywine rivers and

Chesapeake Bay, and by the time of the American Revolution (1775-1783) they

were arguably the most productive in the world. Similar milling technology was

also used to grind snuff and other tobacco products in the same region.

As the 19th century passed,

Americans improved continuous-process technology and expanded its use. The

basic principle of utilizing gravity-powered and mechanized systems to move and

process materials proved applicable in many settings. The meatpacking industry

in the Midwest employed a form of this technology, as did many industries using

distilling and refining processes. Items made using continuous-process

manufacturing included kerosene, gasoline, and other petroleum products, as

well as many processed foods. Mechanized, continuous processing yielded uniform

quantity production with a minimum need for human labor.

|

C2

|

The American System

|

In a closely related development,

by the mid-19th century American manufacturers shaped a set of techniques later

known as the American system of production. This system involved using

special-purpose machines to produce large quantities of similar, sometimes

interchangeable, parts that would then be assembled into a finished product.

The American system extended the idea of division of labor from workers to

specialized machines. Instead of a worker making a small part of a finished

product, a machine made the part, speeding the process and allowing

manufacturers to produce goods more quickly. This method also enabled goods of

much more uniform quality than those made by hand labor. The American system

appeared first in New England in the manufacture of clocks, locks, axes, and

shovels. Around the same time, the federal armories used an advanced version of

this same system to produce large numbers of firearms, coining the term armory

practice.

Soon a group of knowledgeable

mechanics and engineers spread the American system. Many industries began to

use special-purpose machines to produce large quantities of similar or even

interchangeable parts for assembly into finished goods. The American system was

used by inventor and manufacturer Cyrus Hall McCormick to produce his

innovative reapers; Samuel Colt used it to make revolver pistols; and inventor

Isaac Merrit Singer produced his popular sewing machines using this system.

These kinds of products won prizes and attracted much attention at the Crystal

Palace exhibition of 1851.

|

D

|

The Second Industrial

Revolution

|

Bessemer Steel Production

In order to convert molten pig

iron (crude iron) into steel with a Bessemer furnace, air must be blown through

it to burn away impurities. This engraving of a steel factory illustrates the

process developed by Sir Henry Bessemer in 1855 and used until the 1950s.

As American manufacturing

technology spread to new industries, it ushered in what many have called the

Second Industrial Revolution. The first had come on a wave of new inventions in

iron making, in textiles, in the centrally powered factory, and in new ways of

organizing business and work. In the latter 19th century, a second wave of

technical and organizational advances carried industrial society to new levels.

While Great Britain had been the birthplace of the first revolution, the second

occurred most powerfully in the United States.

With the second revolution

came many new processes. Iron and steel manufacturing was transformed in the

1850s and 1860s by vastly more productive technologies, the Bessemer process

and the open-hearth furnace. The Bessemer process, developed by British

inventor Henry Bessemer, enabled steel to be produced more efficiently by using

blasts of air to convert crude iron into steel. The open-hearth furnace, created

by German-born British inventor William Siemens, allowed steelmakers to achieve

temperatures high enough to burn away impurities in crude iron.

Henry Ford

In 1903 American industrialist

Henry Ford established the Ford Motor Company, the leading manufacturer of

affordable cars in the early 1900s.

In addition, factories

and their production output became much larger than they had been in the first

stage of the Industrial Revolution. Some industries concentrated production in

fewer but bigger and more productive facilities. In addition, some industries

boosted production in existing (not necessarily larger) factories. This growth

was enabled by a variety of factors, including technological and scientific

progress; improved management; and expanding markets due to larger populations,

rising incomes, and better transportation and communications.

American industrialist

Andrew Carnegie built a giant iron and steel empire using huge new plants. John

D. Rockefeller, another American industrialist, did the same in petroleum

refining. Soon there were enormous advances in science-based industries—for example,

chemicals, electrical power, and electrical machinery. Just as in the first

revolution, these changes prompted further innovations, which led to further

economic growth.

It was in the automobile

industry that continuous-process methods and the American system combined to

greatest effect. In 1903 American industrialist Henry Ford founded the Ford

Motor Company. His production innovation was the moving assembly line, which

brought together many mass-produced parts to create automobiles. Ford’s moving

assembly line gave the world the fullest expression yet of the Second

Industrial Revolution, and his production triumphs in the second decade of the

20th century signaled the crest of the new industrial age.

|

D1

|

Organization and Work

|

Andrew Carnegie

Andrew Carnegie made millions of

dollars as a pioneer in the American steel industry. He became known for the

legacy of donations—totalling nearly $350 million—that he made to various

charitable causes, including education, research, and art institutions.

Just as important as advances

in manufacturing technology was a wave of changes in how business was

structured and work was organized. Beginning with the large railroad companies,

business leaders learned how to operate and coordinate many different economic

activities across broad geographic areas. During the first phase of the

Industrial Revolution, many factories had grown into large organizations, but

even by 1875 few firms coordinated production and marketing across many

business units. Leaders such as Carnegie and Rockefeller changed this, and

firms grew much larger in numerous industries, giving birth to the modern

corporation.

Within the business unit,

Americans pioneered novel ways of organizing work. Engineers studied and

modified production, seeking the most efficient ways to lay out a factory, move

materials, route jobs, and control work through precise scheduling. Industrial

engineer Frederick W. Taylor and his followers sought both efficiency and

contented workers. They believed that they could achieve those results through

precise measurement and analysis of each aspect of a job. Taylor’s The

Principles of Scientific Management (1911) became the most influential book of

the Second Industrial Revolution. By the early 20th century, Ford’s mass

production techniques and Taylor’s scientific management principles had come to

symbolize America’s place as the leading industrial nation.

|

D2

|

Changes in Agriculture

|

New York City Tenements

During the Industrial Revolution,

thousands of people immigrated to cities to find work. Many had to live in

overcrowded tenement housing, such as this building in New York City.

As it had done in Britain,

industrialization brought deep and often distressing shifts to American

society. The influence of rural life declined, and the relative economic

importance of agriculture dwindled. Although the amount of land under

cultivation and the number of people earning a living from agriculture

expanded, the growth of commerce, manufacturing, and the service industries

steadily eclipsed farming’s significance. The proportion of the work force

dependent on agriculture shrank constantly from the time of the first federal

census in 1790. From that time until the end of the 19th century, farm workers

dropped from about 75 percent of the work force to about 40 percent.

Cyrus Hall McCormick

Inventor Cyrus McCormick

introduced the horse-drawn reaper in 1831. The reaper allowed the average

farmer to harvest his crops five times faster than before. The reaper replaced

the hand scythe, which had been the best harvest tool available for

generations.

New technology was introduced

in agriculture. The scarcity of labor and the growth of markets for

agricultural products encouraged the introduction of machinery to the farms.

Machinery increased productivity so that fewer hands could produce more food

per acre. New plows, seed drills, cultivators, mowers, and threshers, as well

as the reaper, all appeared by 1860. After that, better harvesters and binding

machines came into use, as did the harvester-threshers known as combines.

Farmers also used limited steam power in the late 19th century, and by about 1905

they began using gasoline-powered tractors. At about the same time, Americans

began to apply science systematically to agriculture, such as by using genetics

as a basis for plant breeding. These techniques, plus fertilizers and

pesticides, helped to increase farm productivity.

|

E

|

Changes in Society

|

As in Britain, the Industrial

Revolution in the United States led to major social changes. Urban population

grew, rural population declined, and the nature of labor changed dramatically.

|

E1

|

Growth of Cities

|

As a result of the shift

in economic importance from agriculture to manufacturing, American cities grew

both in number and in population. From 1860 to 1900 the number of urban areas

in the United States expanded fivefold. Even more striking was the explosion in

the growth of big cities. In 1860 there were only 9 American cities with more

than 100,000 inhabitants; by 1900 there were 38. Like the British critics of

the preceding century, many Americans viewed these industrial and commercial centers

as dark and dirty places crowded with exploited workers. But whatever the

drawbacks of city life, urban growth in the United States was unstoppable,

fueled both by the movement of rural Americans and a swelling tide of

immigrants from Europe. In 1790 only about 5 percent of the American population

lived in cities; today more than 75 percent does. This long-term trend is

characteristic of societies experiencing industrialization and is evident today

in regions of Asia and Latin America that are now undergoing an industrial

revolution.

|

E2

|

Effects on Labor

|

Child Labor in Textile Factory

During the Industrial Revolution,

children were employed in factories and worked long hours. This photo by noted

American photographer Lewis Hine shows young boys working at a spinning

machine. Hine’s photographs led to the passing of the first child-labor laws.

Industrialization brought to

the United States conflicts and stresses similar to the ones encountered in

Britain and in Europe. Those who had a stake in the traditional economy lost

ground as mechanized production replaced household manufacturing. Often,

skilled workers found their income and their status under attack from the new

machines and the relentless division of labor. Businesses had always enjoyed

considerable power in their relationships with the labor force, but the balance

tipped even more in their favor as firms grew larger.

In order to counter the

power of business, workers tried to form trade unions to represent them and

bargain for rights. Initially they had only limited success. Occasional

strikes, sometimes violent, appeared as signs of underlying tensions. Until the

Great Depression of the 1930s, skilled craft workers were almost the only

groups able to sustain unions. The most successful of these unions were those

in the American Federation of Labor. They did not seek fundamental social or

economic change, such as socialists advocated; instead they accepted industrial

society and concentrated on improving the wages and working conditions of their

members.

Eventually the United

States digested the tensions and dislocations caused by the coming of industry

and the growth of cities. The government began to enact regulations and

antitrust laws to counter the worst excesses of big business. The Sherman

Antitrust Act of 1890 was created to prevent corporate trusts, monopoly

enterprises formed to reduce competition and allow essentially a single

business firm to control the price of a product. Laws such as the Fair Labor

Standards Act, enacted in 1938, mandated worker protections, including the

maximum 8-hour workday and 40-hour workweek. Above all, the rising incomes and

high rates of economic growth proved calming. Material progress convinced most

Americans that industrialization had been a positive development, although the

challenge of balancing business growth and worker rights remains an issue to

this day.

|

IV

|

THE INDUSTRIAL REVOLUTION

AROUND THE WORLD

|

South Korean Electronic Workers

Agriculture once dominated the

South Korean economy, but export-oriented manufacturing has transformed the

country from one of the world's poorest into an industrial power. About

one-third of South Korea’s labor force is now involved in industry, as are

these workers at a tele-electric company.

After the first appearance

of industrialization in Britain, many other nations eagerly pursued similar

changes. In the 19th century the Industrial Revolution spread not only to the

United States, but also to Germany, France, Belgium, and much of the rest of

western Europe. Often, skilled British workers and knowledgeable entrepreneurs

moved to other countries and taught the manufacturing techniques they had

learned in Britain.

Change happened somewhat

differently in each setting because of varying resources, political conditions,

and social and economic circumstances. In France, industrial development was

somewhat delayed by political turmoil and a lack of coal, but the central

government played a more active role in development than Britain’s had. Both

countries created railroad networks, for example, but the British did so

entirely through private companies, while the French central government funded

much of its country’s railways. Craft production, in which people make

decorative or functional items by hand, also remained a more significant

element in the French economy than it did in Britain. In some industries, such as

furniture manufacturing, the extent of mechanization was not as great as it had

been in Great Britain.

In Germany the central

government’s role was also greater than it had been in Great Britain. This was

partly because the German government wanted to hasten the process and catch up

with British industrialization. Germany used its rich iron and coal resources

to develop heavy industry, such as iron and steel manufacture. It also proved

to be an environment that encouraged big businesses and cooperation among large

firms. The German banking sector, for example, was dominated by a few large

banks that coordinated efforts to increase industry.

Caracas, Venezuela

Caracas, the capital of

Venezuela, is the country’s leading commercial and industrial center. Oil

refining is one of the chief industries. Since the 1950s, construction of many

new high-rise office and apartment buildings has changed the quiet, colonial

city into one of Latin America’s most modern urban areas.

In Russia, the government

made repeated efforts to enable industrialization, sometimes hiring foreigners

to build and operate whole factories. On the whole, however, industrialization

spread more slowly there, and the Russian economy remained overwhelmingly

agricultural for a long time. Even in largely industrialized areas, such as

western Europe and the United States, some areas lagged behind in industrial

development. Southern Italy, Spain, and the American South remained largely

agrarian until much later than their neighbors. In Asia, industrialization

varied, although as a whole it came much later than Western European

development.

In Japan, the first industrial

Asian nation, the central government made industrialization a national goal

during the late 19th century. Industrialization in some areas of China began in

the early 20th century and increased near the end of the century. Other Asian

and Pacific Rim countries, such as South Korea and Taiwan, began to

industrialize after the 1960s.

Smog over Santiago

As the city of Santiago, Chile,

grew more industrialized, it began to face many of the same issues as other

industrial areas. Set in an enclosed valley between the coastal range and the

Andes Mountains, the city experiences high levels of air pollution. In 1997

Chile and neighboring Argentina opened a pipeline to pump natural gas from

Argentina to Santiago. Because natural gas burns much cleaner than other fuels,

Chileans hope the new pipeline will help reduce pollution and improve

Santiago’s air quality.

In Southeast Asia, sub-Saharan

Africa, India, and much of Latin America—areas that were colonies of Western

nations, or that were dominated by other nations for long

periods—industrialization was much more delayed than in many other areas. The

legacies of colonialism made widespread change difficult because the society

and economy of colonies were heavily controlled by and dependent on the parent

country.

Although different cultures

produced distinctive variations of an industrial revolution, the similarities

are striking. Mechanization and urbanization were central to each area in which

the Industrial Revolution succeeded, as were accompanying tensions and

disruptions. In most societies, the truly revolutionary changes came during the

first 75 to 100 years after the process of industrialization began. After that,

factory production dominated manufacturing, and most people moved to cities.

|

V

|

COSTS AND BENEFITS

|

Industrial Smokestacks

Carbon dioxide, sulfur dioxide,

and other types of contaminants pouring from industrial smokestacks contribute

largely to the world’s atmospheric pollution. Carbon dioxide contributes

significantly to global warming, while sulfur dioxide emissions are the

principal cause of acid rain in the northeastern United States, southeastern

Canada, and eastern Europe.

The modern, industrial

societies created by the Industrial Revolution have come at some cost. The

nature of work became worse for many people, and industrialization placed great

pressures on traditional family structures as work moved outside the home. The

economic and social distances between groups within industrial societies are

often very wide, as is the disparity between rich industrial nations and poorer

neighboring countries. The natural environment has also suffered from the

effects of the Industrial Revolution. Pollution, deforestation, and the

destruction of animal and plant habitats continue to increase as

industrialization spreads.

Perhaps the greatest benefits

of industrialization are increased material well-being and improved healthcare

for many people in industrial societies. Modern industrial life also provides a

constantly changing flood of new goods and services, giving consumers more

choices. With both its negative aspects and its benefits, the Industrial

Revolution has been one of the most influential and far-reaching movements in

human history.

No comments:

Post a Comment